Timing can make or break a pipeline construction project. Immediately available inventory offers immediate advantages, delivering bottom-line cost savings and substantial lead time reductions. Re-sourced assets which are unused idle assets resold through peer-to-peer networks, are immediately available while retaining the necessary quality for midstream projects.

The value of available inventory combined with turnkey support creates tangible, bottom-line benefits. In this article, we will walk through three case scenarios that demonstrate the power of having the right inventory, at the right time, in the right place, with optimal support to ensure on-time asset delivery.

Circumventing Extended Lead Times for Accelerated Commissioning and Maximized Profits

Using re-sourced assets, a midstream operator completed a project early, commissioning its newly constructed expansion ahead of schedule. This particular expansion project demanded large quantities of 36” pipe with accompanying lead times between 3-5 months.

Like most pipeline projects, the operator faced an uphill battle to complete the line on time and within budget. In addition, an unfriendly political environment for new pipeline construction and high interest rates set the scene for a complicated project timeline.

Several factors impacted the excessive lead times forecasted for the needed construction materials. An unwieldy backlog coupled with pervasive supply chain issues and chronic labor shortages cast a dim outlook on the possibility of on-time delivery. To mitigate further delays, the operator began to explore additional options that could meet the rigorous requirements for high-pressure pipeline construction.

The materials required traceable, verified, and complete (TVC) records, including MTRs (material test reports), and other required documentation. Using re-sourced assets that were immediately available and on the ground, the operator and its inspection providers inspected the assets in real-time. The same assets that were inspected upfront by the operator would be used in the final project, allowing for maximum certainty in their quality prior to installation.

In the end, the new pipeline construction project was not only completed on time, but ahead of schedule, making it one of the few large-scale pipeline projects in recent years that managed to avoid public scrutiny and negative press.

Accessible Inventory Leads to Cost Reductions and Faster Project Timelines

Using re-sourced inventory, an operator reduced project material acquisition costs by 15-30% and expedited the project timeline. This major oil and gas operator needed pipe and valves to build a 68-mile line. To ensure the successful completion of the project, the operator needed to acquire not only the necessary material, but also the required documentation for technical review and approval.

At the time of this project, the estimated manufacturing lead times for line pipe were close to 4-6 months while valves were 50+ weeks. These delayed lead times were the result of supply chain inefficiencies and labor shortages, and the resulting consequences threatened negative impacts on construction costs as well as potential commercial repercussions for the operator.

Both line pipe and valves were available through re-sourcing with ARS Global. With immediately available re-sourced inventory, the operator took advantage of faster delivery while meeting quality control and documentation requirements. Ultimately, the operator achieved between 15-30% cost savings through re-sourcing instead of ordering newly manufactured project materials.

Protecting Against Market Volatility with Re-Sourced Alternatives

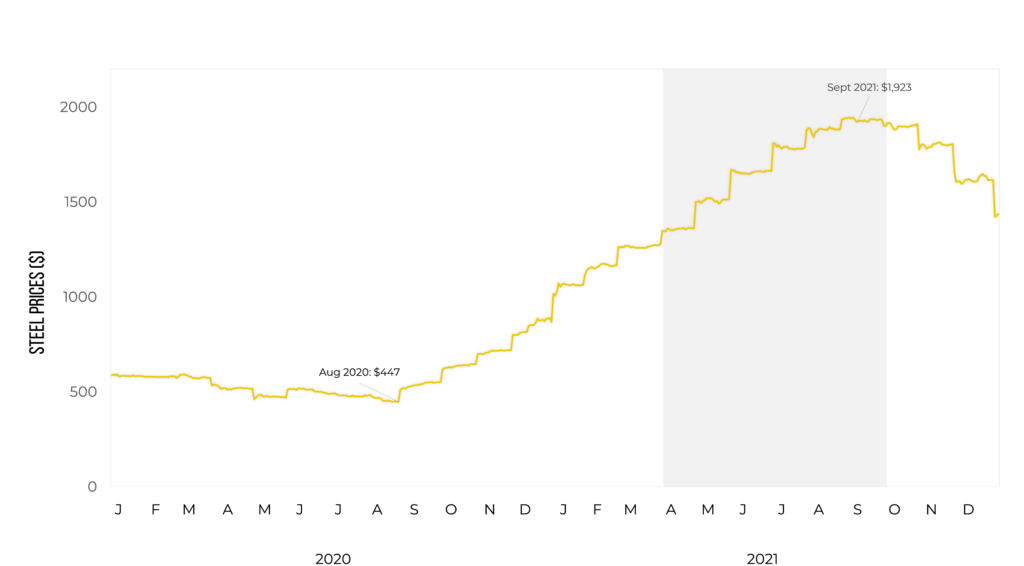

COVID-19 presented extraordinary circumstances, including many that affected the pipeline industry. Astronomically high steel price increases and sudden project cancellations were just a few of the many instabilities that accompanied the onset of the pandemic.

After an unexpected pipeline construction project cancellation, an operator was left holding excessive quantities of high-quality, newly manufactured materials on its books. The operator was looking to recover its investment and divest the assets, including selling readily available 42” pipe. Simultaneously, another pipeline operator was looking to complete a pipeline construction project that required large amounts of the same size pipe for a 130-mile construction project that was fast approaching.

Taking advantage of peer-to-peer networks, both the buyer and seller of the pipe successfully divested and acquired the appropriate project materials. The buyer managed to reduce project material acquisition costs by 30% and avoided a volatile steel market. The seller was fairly compensated and successfully recovered the value of the assets that would no longer be used for a project.

Learn More About Immediately Available Inventory With Peer-to-Peer Sourcing

ARS Global has immediately available pipe, valves, and fittings through re-sourcing, or the resale of unused, ready-to-deploy assets. All inventory is supported with turnkey services, documentation, and transportation. Learn more about how to satisfy project requirements while saving time and money at arsglobal.com.